What is Gr.1 Titanium? Features of Gr.1?

Gr.1 titanium plate is an industrial pure titanium plate. Gr.1 titanium plate has high mechanical properties, excellent stamping performance, and can be welded in various forms. The strength of the welded joint can reach 90% of the strength of the base metal, and Good cutting performance.

Titanium tubes have high corrosion resistance to chlorides, sulfides and ammonia. The corrosion resistance of titanium in seawater is higher than that of aluminum alloy, stainless steel, and nickel-based alloys. Titanium also has strong water impact resistance. Titanium alloys work in humid atmosphere and seawater media, and their corrosion resistance is far superior to that of stainless steel; they are particularly resistant to pitting corrosion, acid corrosion, and stress corrosion; they are resistant to alkali, chloride, Chlorine organic substances, etc. have excellent corrosion resistance. However, titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.

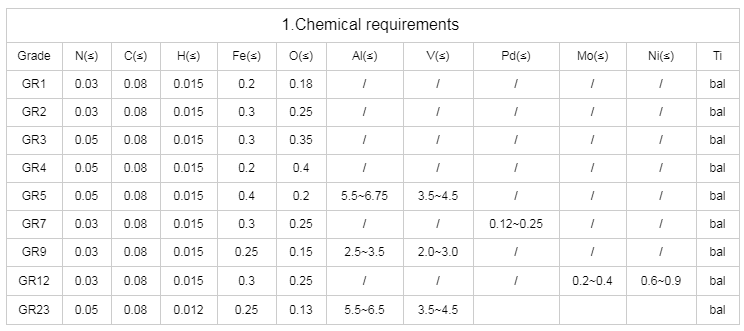

Chemical composition and performance of Gr.1 titanium ?

titanium grades comparison

The performance of Gr.1 titanium plate is related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purest titanium iodide impurity content does not exceed 0.1%. Gr.1 titanium plate has low strength and high plasticity.

The properties of 99.5% industrial pure titanium are: density 4.5g/cm3, melting point 1725°C, thermal conductivity 15.24W/(m.K), tensile strength 539MPa, elongation 25%, reduction of area 25%, elastic modulus 105MPa , the hardness is HB195, the chemical activity of titanium is large, and it has a strong chemical reaction with O, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere. When the carbon content is greater than 0.2%, hard TiC will be formed in the titanium alloy; when the temperature is high, it will also form a hard surface layer of TiN when it interacts with N; when it is above 600°C, titanium absorbs oxygen to form a hardened layer with high hardness ; When the hydrogen content rises, an embrittlement layer will also be formed. The depth of the hard and brittle surface layer produced by absorbing gas can reach 0.1-0.15 mm, and the hardening degree is 20%-30%.

The chemical affinity of titanium is also large, and it is easy to cause adhesion with the friction surface.

Materials Comparison titanium grade 2