1. What is tungsten, molybdenum ion implantation?

Tungsten, molybdenum ion, is the formation of atoms or molecules after ionization, and with electricity, through the electric field of ion movement, the use of magnetic field to change its direction of movement, the use of ion implantation machine, can make tungsten, molybdenum ion injection into the matrix, mainly used in the semiconductor industry.

2. What are the characteristics of tungsten and molybdenum ion implantation?

- The content of doping can be controlled.

- Can accurately control the injection direction and depth.

- High uniformity.

- Can produce a single ion beam

3. Fractional injection of tungsten and molybdenum ions

In order to make the ion distribution even, fractional injection can be carried out.

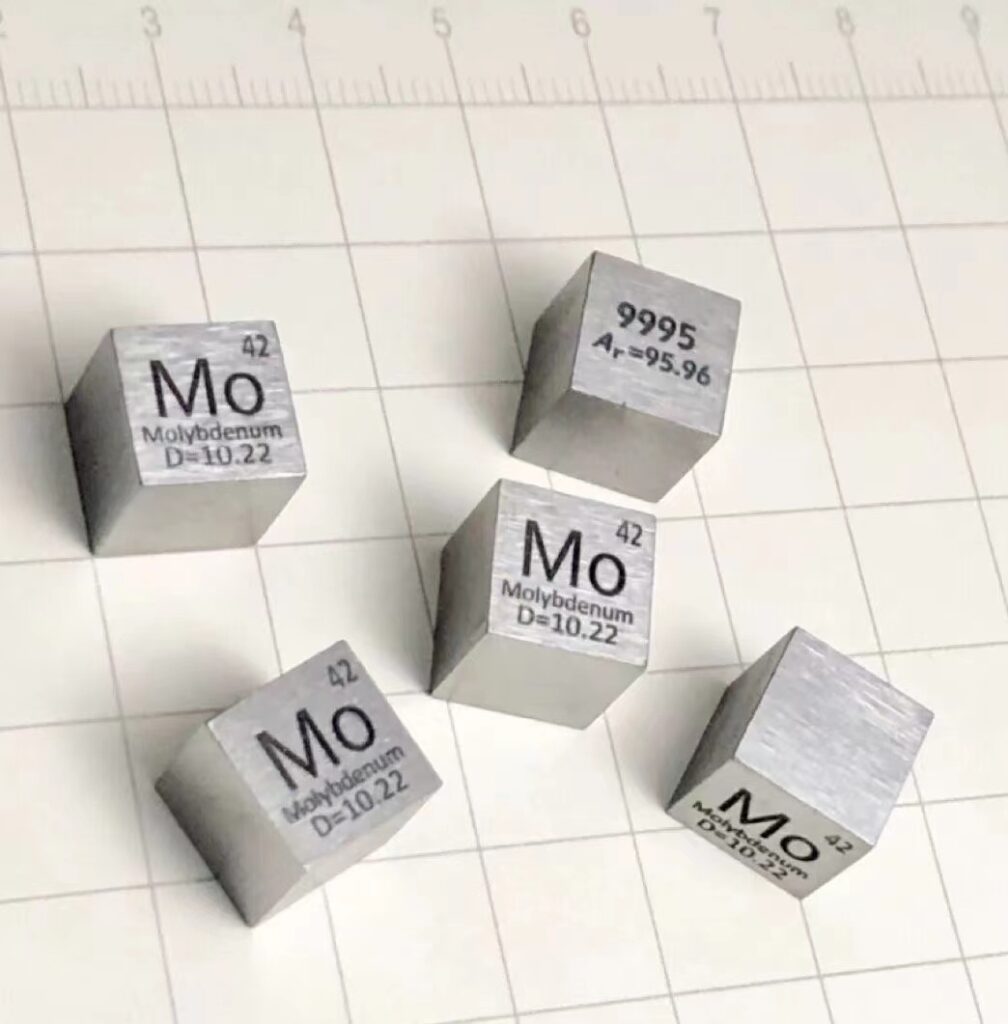

Tungsten, molybdenum metal material high temperature chemical properties are stable, so commonly used metal tungsten, molybdenum.

4. Ion implantation process

By ion implantation into a semiconductor material, it changes its electronic structure, as well as its electrical conductivity. Ion implantation technology realizes the optimization of surface properties of materials, and is a very important technology in modern integrated circuit manufacturing. It uses ion implanter to dope the semiconductor and change the conductivity and transistor structure of the semiconductor. Tungsten and molybdenum metal materials have become the first choice of ion consumables for ion implantation machines in the semiconductor industry, and the shielding cylinder of the emission cathode, the emission panel, the center fixed rod, and the wire plate in the arc room are all collectively called ion implanted tungsten parts.

5. Requirements for ion implantation in the semiconductor industry.

For ion implantation technology, the purity of tungsten and molybdenum metal is very high, usually using high purity 4N,4N5,5N and other purity tungsten and molybdenum metal as consumables.

6. Why use tungsten metal for ion implantation?

The melting point of tungsten metal is extremely high, which can reach 3410 degrees Celsius, and tungsten wire is often used in heating principles such as filament. Tungsten metal with excellent performance, in modern industry, semiconductor field has one of the indispensable raw materials. Ion implanted tungsten parts have good high temperature performance and are often used in modern integrated circuit manufacturing industry.

Top Star Metal Supply:

The company’s leading products include titanium, tungsten, molybdenum, tantalum, niobium materials and its seamless pipe, sheet, foil, bar, flange pipe, pipe, pressure vessel, casting forgings, standard parts and other products are widely used in chemical industry, military industry, metallurgy, petroleum equipment, seawater desalination, pharmaceutical, electroplating, shipbuilding, paper making, medical, semiconductor and other fields.