With the rapid development of the city, the scale of rail transit is gradually expanding, the network operation is increasing, the energy consumption is increasing, the rail transit vehicles are running more and more widely, the speed is getting faster and faster, and the high-performance metal material titanium alloy is beginning to apply to the rail transit industry.

With the promotion of rail construction at the same time, the transportation equipment manufacturing industry is also growing rapidly, and new materials, new technologies, and new processes for the application of rail transit are also developing rapidly. Compared with traditional metal materials, the excellent properties of titanium alloy are very suitable for rail transit vehicles. Titanium alloy has the advantages of light weight, high specific strength, good mechanical properties, high temperature resistance, low temperature, corrosion resistance, etc., which has been applied in the rail transit industry, and gradually researched and applied in the production and manufacturing process.

1. Advantages Of Titanium Alloy

The excellent properties of titanium alloy have been applied in aerospace, petrochemical, Marine construction, water treatment, medical, automotive and other industries.

- Low density and light weight: titanium has a density of 4.51g/cm3, but its specific strength ranks first among metals.

- High strength: the tensile strength, elongation and mechanical properties of titanium alloy are excellent. Often used in aircraft turbines, engines and other Boeing aircraft parts.

- Long-term operation at high temperatures and low temperatures, long service life: One of the best properties of titanium alloy is that it can maintain a long working state at high temperatures and low temperatures.

- Corrosion resistance: The oxygenophilic properties of titanium can form a dense oxide film with oxygen elements to protect the matrix from corrosion, often used in Marine water, humid atmosphere and other environments, corrosion resistance is much greater than ordinary materials and stainless steel, and many materials also use pure titanium coating for protection.

2.Application Of Titanium Alloy In Rail Transit

With the increase of lightweight requirements for rail transit, titanium alloy parts have gradually begun to be applied, such as car bodies, bogie frames, equipment silo and so on.

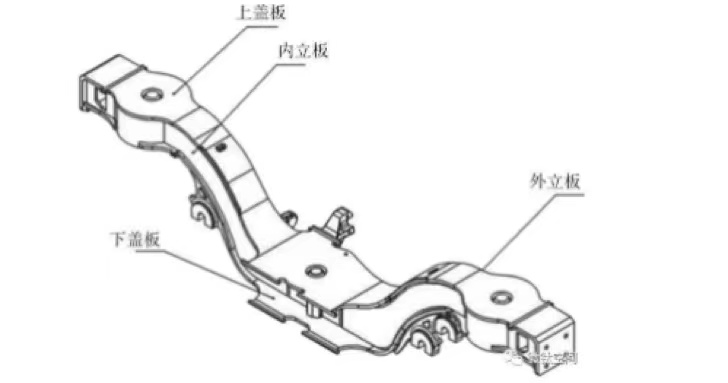

The Bogie Frame

Bogie is one of the important components of rail vehicles, and the frame is also the skeleton of the bogie, which is the installation basis of other parts of the bogie (such as induction motor, current receiver, speed sensor, unit brake cylinder, and various shock absorbers). Various sophisticated and complex mechanical, electrical and braking equipment are integrated on the bogie according to different technical process requirements, and play the role of transmitting traction, braking force, lateral force and vertical force in the operation of the vehicle. The use of titanium alloy frame, fully achieve high strength, lightweight structure.

Titanium Alloy Axle Box

The connecting wheel and the parts of the bogie frame are axle boxes, which are used to transfer the weight and load of the car body and frame to the wheel set, lubricate the journal, reduce friction and reduce resistance. The axle box is a typical unsprung weight, therefore, the lightweight of the axle box plays an important role. Modern metal materials use cast steel. The tensile strength is greater than 620Mpa, the yield strength is less than 415Mpa, and the elongation is greater than 22%. The outstanding performance of titanium alloy can fully meet the above needs.

Titanium Alloy Transition Coupler

The transition coupler is connected to the car of two different models of cars, mainly to ensure that the dispatching driver smoothly transfers the vehicle to be inspected, which requires personnel handling, in order to ensure safety and lightweight embodiment, it is particularly important. The designed transition coupler, with a single hook weight of about 20kg, did not break in the 750KN tensile load test and 800KN compression load test. The test results show that the titanium alloy meets the needs of safety tests in terms of weight and mechanical properties.

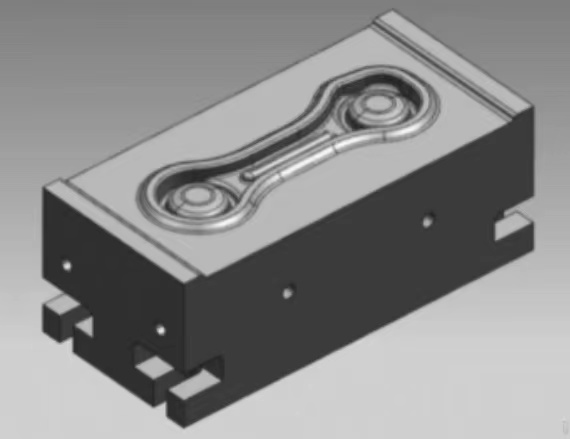

Titanium alloy pull rod

It is mainly to achieve the connection of the car body and the bogie, the transmission of traction and braking force, titanium alloy can not only play a vibration reduction effect, but also can use die forging forming and machining to improve the utilization rate.

TOP STAR METAL MATERIALS CO.,LTD SUPPLY:

Gr1,Gr2,Gr4,Gr5 Gr7 Gr9 Gr12

Ti6Al4V (GR5, GR23, Ti6Al4V ELI), Ti6242 Ti811, GR16, GR7, GR9, GR12, GR6, TA15, TC1 and TC2, etc

ASTM B265/ASTM F136 /ASTM F67

AMS4901, AMS4902, AMS4904, AMS4907, AMS4914, AMS4916, AMS4919