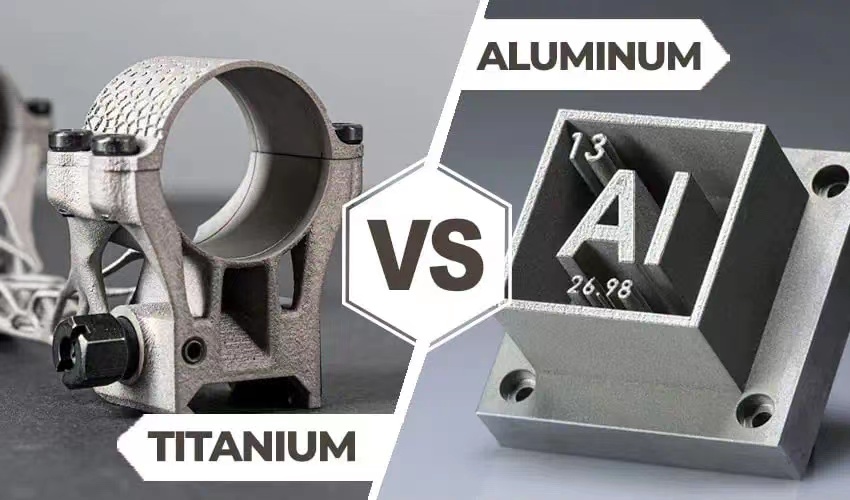

Titanium metal is a low-density, corrosion-resistant, lightweight metal material, compared with stainless steel, aluminum and other metals, his low density, high strength, and high biocompatibility, often used in medical, dental and so on. Excellent mechanical and physical properties, making titanium and titanium alloy, chemical and petroleum, sewage treatment, Marine, automotive, medical, aerospace has a wide range of applications, is an excellent metal material.

1.What are the materials of titanium alloy in 1.3D printing?

The most commonly used titanium alloy is GR5 Ti6Al4V, which has Al and V elements, making GR5 titanium alloy has high strength, high temperature resistance, good low temperature performance, strong mechanical properties and other characteristics.

is widely used in the medical industry because of its low oxygen content and high biocompatibility. 3D printing combines information technology and manufacturing technology to manufacture titanium alloy workpieces through three-dimensional models. Greatly save the manufacturing cost, reduce the production of abrasive tools and other processes. And 3D printing technology, high precision, intelligent, is a major breakthrough in the field of titanium alloys.

Application of pure titanium GR1 GR2

The titanium content of pure titanium GR1 and GR2 is greater than 99.6%, of which high-purity titanium 4N, 4N5, can reach a purity of 99.95% 99.99% 99.995% or more, compared with titanium alloy, its purity is the highest.

Ti-6.5Al-2Zr-1Mo-1V

is one of the aerospace titanium alloy materials, his high temperature resistance is good, high temperature above 650 degrees Celsius, can work for a long time. And has good plasticity, strength, mechanical properties are also excellent. Therefore, it is often used in the manufacturing of Boeing aircraft parts, engine parts, etc., among which titanium alloy ultra-thin plates, titanium alloy forgings, titanium alloy forged rings, etc.

2.What are the characteristics of titanium alloys?

Compared with stainless steel, titanium alloy has the characteristics of lightweight, and its use in aerospace can reduce its weight and save fuel costs. Strong mechanical properties, after titanium alloy forging, titanium alloy hot rolling, titanium alloy cold rolling, titanium alloy annealing, titanium alloy stress annealing and other processes, change the molecular structure, can enhance its mechanical properties, which tensile strength, elongation, have been significantly improved.

3.What is titanium alloy 3D printing technology?

Titanium alloy 3D printing technology is a powder bed fusion process of powdered titanium. Laser Powder Bed Melting (LPBF) is a powder manufacturing technology for high power lasers. Electron beam powder bed fusion technology EB PBF, the difference is that the use of an electron beam, in the powder bed fusion process, titanium alloy 3D printer from the titanium metal powder bed, for selective scanning. All geometric information is provided to the printing system from the CAD model previously defined in the 3D modeling software. The main characteristics of powder materials are particle morphology and particle size distribution. The spherical shape is required to allow the powder to have good fluidity while the printing process is going on. The manufacturing process of the powder determines its final properties. Metal powders can be manufactured by gas atomization, rotary atomization, plasma rotating electrode method, and water atomization.

TOP STAR METAL MATERIALS CO.,LTD Supply:

Materials:Ti6Al4V(GR5、GR23、TC4、TC4ELI)、Ti6242(TA19)、Ti811(TA11)、GR16(TA8)、GR7(TA9)、GR12(TA10)、GR9(TA18)、GR6(TA7)、TA15、TC1、TC2…

Standard:AMS4901、AMS4902、AMS4904、AMS4907、AMS4911、AMS4912、AMS4913、 AMS4914、AMS4916、AMS4919、AMS4928、ISO5832-2/3、ASTM F136、ASTM F67、GJB2505、GJB2919、GJB2744、GJB2218、GB/T3621、ASTM B265

Products: Titanium plate, titanium rod, titanium forgings, titanium straight wire, titanium disc wire, titanium seamless pipe, titanium welded pipe, titanium flanged flange, titanium square, titanium air exchanger tube, titanium equipment, titanium screws and nuts, etc