L605 alloy is mainly composed of cobalt chromium tungsten nickel and other elements, it has excellent high temperature strength and corrosion resistance, can remain stable at high temperatures, but also has strong oxidation resistance, so it is often used in aerospace parts, petrochemical, automotive and other industries.

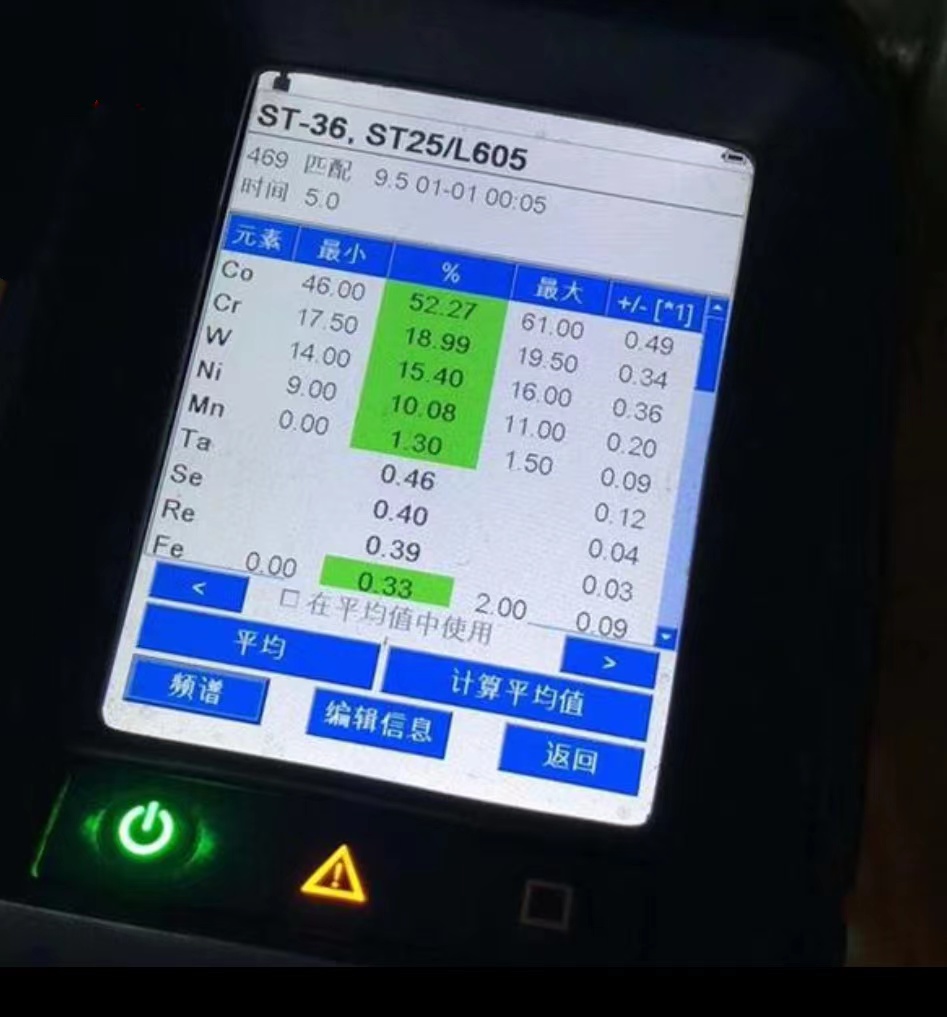

1.L605 Chemical elements of cobalt-chromium-tungsten-nickel alloy

- Tensile strength 1210σb/MPa

- Yield strength 340σp0.2/MPa

- Elongation 35σ5 /%

- Brinell hardness 282 HBS

- Product: L605 forged ring

- Standard AMS 5759

Size:

16.2 “✖ ️ 15.3″ ✖ ️ 1”

17.2 “✖ ️ 15.7″ ✖ ️ 1.5”

9.5 “✖ ️ 8.1″ ✖ ️ 1.5”

2.L605 cobalt-chromium-tungsten-nickel alloy material analysis

The composition of L606 alloy including Co,Cr,W,No,No elements can improve its corrosion resistance, of which the Mo element in L605 alloy can improve its strength and hardness. The expansion coefficient of L605 alloy is very low, so in the ultra-high temperature environment, it can continue to work, and has good thermal stability, which is high thermal conductivity, so in the high temperature environment, heat dissipation is relatively fast. In the electronic and electrical industry, L605 alloy has good magnetic properties, so it is widely used in electronic components and magnetic equipment. Among them, the most widely used aerospace industry, L605 ultra-high mechanical properties, high strength, as well as tensile strength, elongation, and yield strength, are far superior to other metal materials, L605 cobalt chromium tungsten nickel alloy tensile properties can reach more than 1000MPa, at a high temperature of 800, can still be maintained above 450MPa. Therefore, the L605 alloy is mostly used in jet engine parts, engine blades, turbine rings and so on.

L605 Alloy Testing

Inspection report, penetration testing, magnetic testing, non-destructive testing, dimensional inspection, etc