- Top Star Metal Materials Co.,Ltd

Alloy MP35N Nickel-cobalt alloy

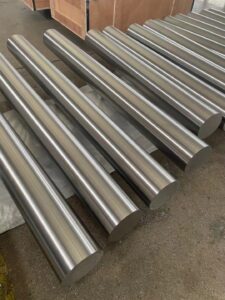

Nickel-cobalt alloy rods

UNS R30035

Anneal 800-1000 N/mm2

Spring toughness 1400-1900 N/mm2

Spring toughness + aging 1900-2200 N/mm2

The rigid modulus is 80.7kN /mm2

Elastic modulus 234 kN/mm2

Standards: AMS5758, AMS5844, AMS5845, ANSI/ASTM F562

Alloy MP35N is an ultra-high tensile strength alloy with good plasticity and toughness of Co-Ni-Cr-Mo alloy containing 35% nickel, 35% cobalt, 20% chromium and 10% molybdenum, as well as corrosion resistance, commonly used in extreme environments. Usually in seawater, it also has excellent resistance to crevice corrosion and stress corrosion.

| Alloy MP-35N | C | Mn | P | S | Si | Cr | Ni |

| Element% | <0.03 | <0.15 | <0.015 | <0.010 | <0.15 | 19-21 | 33-37 |

| Mo | Ti | Pe | Fe | Co | |||

| 9-10.5 | <1.0 | 0.01 | 1 | other |

Annealing: The annealing temperature of MP35N is 1038-1093°C, 1-4 hours, and then air-cooled.

Hot working: Working temperature 1177 degrees Celsius, forging

Cold deformation strengthening: 3-5 times higher than solid solution strength

Aging heat treatment: can increase the strength by more than 30%

1. Elements such as cobalt, nickel and molybdenum in Alloy MP35N improve corrosion resistance. In addition, MP35N shows good service life in hydrogen sulfide environments.

2.Alloy MP35N is one of the high-strength alloys in extreme environments and does not suffer from stress corrosion cracking, which can easily occur in other alloys.

3.AlloyMP35N alloy can be used in medical, seawater, oil and gas Wells, chemical, natural gas, etc.

4. Capillary tubes in Alloy MP35N are widely used in the medical industry.

Product Show

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.