- Top Star Metal Materials Co.,Ltd

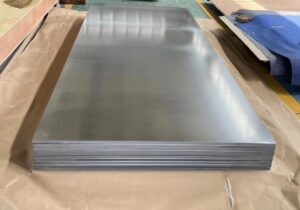

Titanium Sheet AMS 4919

Thickness 0.5-210mm

Cold rolling

hot Rolling

annealing

AMS 4919 Titanium plate has the advantages of low density, light weight, corrosion resistance and good high temperature performance. It is often used in aerospace parts and turbine parts, and plays an important role in the aerospace industry.

Ti6242 (Ti6Al2Sn4Zr2Mo) is a titanium alloy, and unlike ordinary titanium alloys, it has excellent mechanical properties, high temperature stability, and creep resistance. Ti6242 is the highest temperature performance of all titanium alloys.

Forging process performed above recrystallization of metal.

Rolling process carried out at temperatures higher than recrystallization. Cold rolling process in which plastic deformation temperature is lower than temperature.

A metal heat treatment process in which the metal is slowly heated to a certain temperature, held for a sufficient time, and then cooled (usually slowly cooled, sometimes controlled cooled) at a suitable rate.

The part is immersed in an aqueous solution such as acid to remove the oxide film on the surface of the metal. It is the pre-treatment of electroplating, enamel, rolling and other processes.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.