- Top Star Metal Materials Co.,Ltd

Name:Hastelloy B2 (UNS N10665) Tube

Material:UNS N10665

Diameter:3-550mm

Thickness:0.3-150mm

Length:2000-6000mm

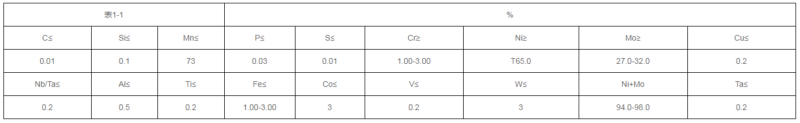

Hastelloy B2 (N10665) is a nickel-based superalloy composed of nickel, molybdenum, cobalt and other elements, with a nickel content of about 65%. Hastelloy b3 (N10675) nickel-based alloy material is a new material improved on the basis of Hastelloy B2, which improves the thermal stability of the material, thereby improving the corrosion resistance, and improving the hot forming and cold forming performance.

Hastelloy B2 (N10665) It is very important that the workpiece should always be kept clean and free from contamination before and during heat treatment. During the heating process, the workpiece cannot touch sulfur, phosphorus, aluminum and other low-melting point metals, otherwise it will damage the properties of the alloy and make the alloy brittle. The heating furnace is an electric furnace. If a gas or oil furnace is used, the lower the sulfur content in the fuel, the better. According to the recommendation of the material manufacturer, the total sulfur content in natural gas and liquefied petroleum gas is not more than 0.1% (V). The sulfur content is not more than 0.25g/m3, and the sulfur content in fuel oil should be less than 0.5% (W), which is better.

Furnace gas must be clean and preferably slightly reductive. Fluctuation between oxidizing and reducing properties of the furnace gas should be avoided, and the heating flame should not directly contact the workpiece. The workpiece must be supported before entering the furnace to avoid undesirable deformation under high temperature. The heating speed of the workpiece should be as fast as possible, and the workpiece cannot be put into the furnace until the furnace temperature reaches the heat treatment temperature. After it is out of the oven, it should be quickly water-cooled. Use the immersion method or evenly spray the entire area. It is strictly forbidden to use water pipes to prevent uneven heat and cold, resulting in abnormal deformation or tearing.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.