- Top Star Metal Materials Co.,Ltd

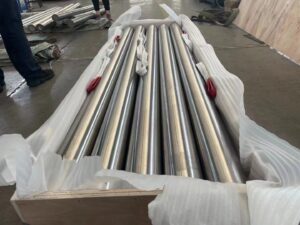

Hastelloy B2 bar

Sheet: ASTM B333

Seamless pipe: ASTM B622

Welded pipe: ASTM B619 ASTM B626

Bar: ASTM B335

Forging: ASTM B564

The main components of Hastelloy B2 are nickel and molybdenum, is a nickel-molybdenum alloy, density: ρ=9.2g/cm3, melting point: 1330 ~ 1380℃, is a low-carbon, silicon, iron strengthened solid solution alloy, has excellent corrosion resistance, has good tolerance to stress corrosion, widely used in chemical, petroleum, energy and other industries.

| Hastelloy B2 | Ni | Cr | Fe | C | Mn | Si | Cu |

| Element% | other | 0.4-0.7 | 1.6-2.0 | <0.01 | <1.0 | <0.08 | <0.5 |

| Mo | Co | P | S | / | / | / | |

| 26-30 | <1.0 | <0.02 | <0.01 | / | / | / |

Corrosion resistance: It has obvious resistance to extreme environment such as acid and alkali, and has strong corrosion resistance in solution.

High hardness: Hastelloy B2 has high strength and hardness.

It has good resistance to chloride ion reduction stress corrosion cracking

Good weldability

Hastelloy B2 Standard

Sheet: ASTM B333

Seamless pipe: ASTM B622

Welded pipe: ASTM B619 ASTM B626

Bar: ASTM B335

Forging: ASTM B564

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.