- Top Star Metal Materials Co.,Ltd

Density: 8.9 g/cm3

Melting point: 1325-1370 ℃

Tensile strength Rm N/mm2: 690

Yield strength RP0.2N/mm2: 283

Elongation A5%: 40

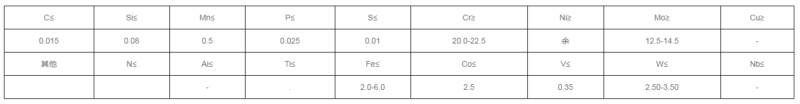

The alloy is a nickel-based superalloy composed of elements such as nickel, molybdenum, cobalt, and tungsten, with a nickel content of about 60%. It is an all-around nickel-molybdenum-cobalt-tungsten alloy with better overall corrosion resistance than other existing nickel-molybdenum-cobalt-tungsten alloys, including Hastelloy C-276, C4 alloy and 625 alloy. Hastelloy C22 alloy has good resistance to pitting corrosion, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media, including wet chlorine, nitric acid or mixtures of oxidizing acids containing chloride ions.

hastelloy c22 mechanical properties

At the same time, HastelloyC22 (N06022) Hastelloy also has the ideal ability to resist the reducing and oxidizing environments encountered in the process. Relying on this versatile performance, it can be used in some troublesome environments, or in a multi-purpose factory application. Hastelloy C22 (N06022) alloy has exceptional resistance to various chemical environments, including strong oxidizing substances, such as ferric chloride, copper chloride, chlorine, thermally polluted solutions (organic and inorganic), formic acid, acetic acid, acetic acid , seawater and saline solutions, etc. Hastelloy C22 (N06022) alloy has the ability to resist the formation of grain boundary precipitation in the welding heat affected zone, which makes it suitable for many chemical process applications in the welded state.

hastelloy c22 alloy uns n06022

Hastelloy C22 alloy is suitable for a variety of chemical process industries containing oxidizing and reducing media. The higher content of molybdenum and chromium makes the alloy resistant to the corrosion of chloride ions, and the tungsten element further improves its corrosion resistance. Hastelloy C22 is one of the few materials that can resist the corrosion of moist chlorine, hypochlorite and chlorine dioxide solutions. The alloy has excellent corrosion resistance to high concentration chloride salt solutions (such as ferric chloride and copper chloride).

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.