- Top Star Metal Materials Co.,Ltd

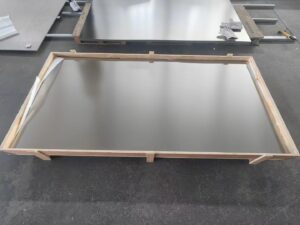

Hastelloy X AMS 5536 Plate

AMS 5536

Tickness:0.5-1.2mm

L:1200*3000mm

Heat Treatment: 2125°F (1163°C)

Tensile Strength: 105 ksi (MPa) min

Hastelloy X is a nickel-based high-temperature alloy with high iron content mainly solid-solution strengthened by chromium and molybdenum. And creep strength, good cold and hot processing formability and welding performance. Used in the manufacture of combustion chamber components and other high-temperature components of aero-engines, long-term use below 900°C, and short-term operating temperatures up to 1080°C.

| Element | C | Mn | Si | P | S | Cr | Co |

| Content(%) | 0.05-0.15 | <1.0 | <1.0 | <0.04 | <0.03 | 20.5-23 | 0.5-2.5 |

| Mo | W | Fe | Al | Ti | Ni | / | |

| 8.0-10 | 0.2-1.0 | 17-20 | <0.5 | <0.15 | Balance | / |

Hastelloy X alloy has excellent corrosion resistance and thermal stability, and is widely used in aviation and chemical fields. Hastelloy X has excellent oxidation resistance and high temperature strength, and is one of the widely used engineering materials in nickel-based alloys. Due to its oxidation resistance, it still has high hardness after long-term exposure to high temperature environment, and can resist stress corrosion cracking. It is widely used in combustion zone heat shields, combustor casings, exhaust pipes and nacelle heaters of gas turbine engines.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.