- Top Star Metal Materials Co.,Ltd

Name:Inconel 600 ( N06600 )

p=8.43g/cm3

Melting temperature range: 1370~ 1430C

Size:custom

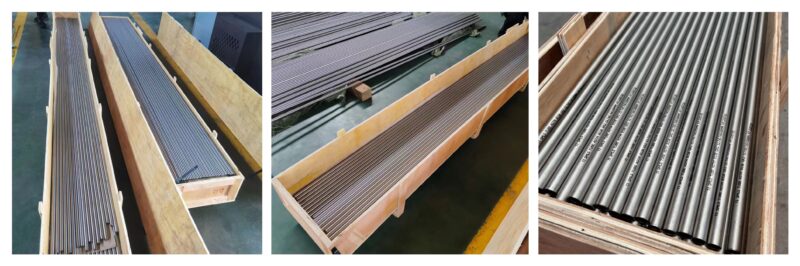

Length:2000mm

Package:wooden box

1.Good resistance to reduction, oxidation and nitriding medium corrosion

2.Good resistance to stress corrosion cracking at room temperature and high temperature

3.It has good corrosion resistance to dry chlorine gas and hydrogen chloride gas

4.Good mechanical properties at subzero, room temperature and high temperature

5.It has good creep rupture strength and is recommended to be used in a working environment above 700°C.

Metallographic structure of Inconel 600

Inconel 600 alloy is corrosion resistant to a variety of corrosive media. The composition of chromium gives this alloy better corrosion resistance in oxidizing conditions than Nickel 99.2 (Alloy 200) and Nickel 99.2 (Alloy 201, low carbon). At the same time, the higher nickel content makes the alloy have good corrosion resistance in reducing conditions and alkaline solutions, and can effectively prevent chloride-iron stress corrosion cracking. Alloy 600 has good corrosion resistance in acetic acid, acetic acid, formic acid, stearic acid and other organic acids, and moderate corrosion resistance in inorganic acids. Excellent corrosion resistance in high-purity water used in primary and secondary cycles in nuclear reactors. The outstanding performance of 600 is that it can resist the corrosion of dry chlorine and hydrogen chloride, and the application temperature is up to 650 ℃. At high temperature, the alloys in the annealed and solution-treated states have good oxidation spalling resistance and high strength in air. The alloy is also resistant to ammonia and nitriding and carburizing atmospheres, but when the redox conditions are alternately changed, the alloy will be corroded by partial oxidizing media

Inconel 600 Application Areas Application Areas

1.Thermowells in aggressive atmospheres

2.Vinyl chloride monomer production: resistance to chlorine, hydrogen chloride, oxidation and carbonization corrosion

3.Oxidative conversion of uranium to hexafluoride: resistance to hydrogen fluoride corrosion

4.Production and use of corrosive alkali metals, especially in environments where sulfides are used

5.Preparation of titanium dioxide by chlorine method

6.Production of organic or inorganic chlorides and fluorides: resistance to chlorine and fluorine corrosion.

7.Nuclear reactors.

8.Retorts and components in heat treatment furnaces, especially in carbonizing and nitriding atmospheres.

9.The catalytic regenerator in petrochemical production is recommended to use alloy 600 in applications above 700°C for longer service life.

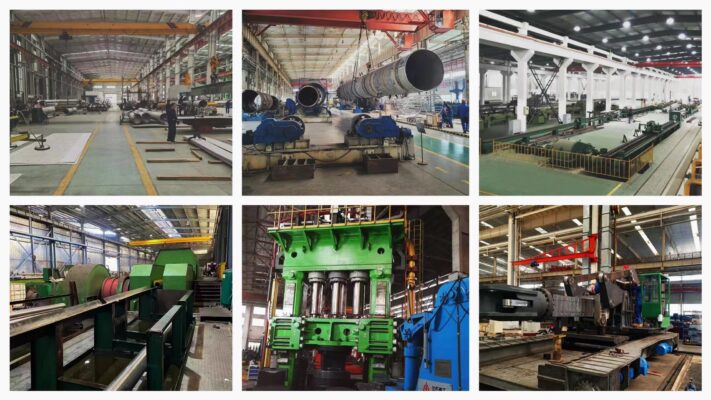

Our company has a professional technical team, has strict control of materials and standards, and has mature technologies in hot rolling and cold rolling, forging, annealing, and we have chemical composition, mechanical properties, flaw detection, penetration and other aspects of products. Testing, with authoritative certification.

Our company has advanced equipment, including forging equipment. Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shape and size. Forging (forging and Stamping) one of the two major components. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. At the same time, we also have pipe welding machines, CNC lathes, milling machines, CNC machining centers and other equipment to produce each product with high quality.

We use export standard fumigated wooden boxes, pearl film for wrapping, and cling film for surface protection, and do every detail well in an all-round way.

Top Star Metal Materials Co.,Ltd

E-mail:Abby@topstitanium.com

E-mail:sales@topstitanium.com

Whatsapp: 86-18292713888

Tel: 86-18292713888

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.