- Top Star Metal Materials Co.,Ltd

Name:lnconel 625 (N06625) Tube

Diameter:5-550mm

Thickness:03-150mm

Length:2000-6000mm

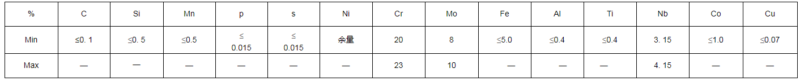

inconel alloy 625 ,It is a Ni-Cr based solid solution strengthened deformed superalloy, a solid solution strengthened nickel based deformed superalloy with molybdenum and niobium as the main strengthening elements, with a service temperature of 950°C and good tensile properties from low temperature to 980°C And fatigue performance, good processing and welding performance, the alloy has excellent corrosion resistance and high oxidation performance, and is resistant to stress corrosion in salt spray atmosphere.

Inconel 625 alloy has excellent corrosion resistance, oxidation resistance and good mechanical properties. Due to its excellent corrosion resistance and high temperature performance, it has a wide range of applications. It is often used in gas turbine engines, nuclear power equipment and aerospace engines. It is especially suitable for those who need to contact seawater and require high mechanical performance.

Inconel 625 is a corrosion and oxidation resistant nickel alloy used for its high strength and excellent resistance to water corrosion. Its exceptional strength and toughness are due to the addition of niobium, which together with molybdenum hardens the alloy’s matrix. Alloy 625 has excellent fatigue strength and stress corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is often used to weld AL-6XN. This alloy is resistant to a variety of severely corrosive environments and is particularly resistant to pitting and crevice corrosion.

Applications: Some typical applications of Inconel 625 are chemical processing, aerospace and marine engineering, pollution control equipment, and nuclear reactors. Soft annealed low-carbon alloy 625 is widely used in the chemical process industry, and its good corrosion resistance and high strength enable it to be used as a thinner structural component. Alloy 625 can be used where it is in contact with seawater and subjected to high mechanical stress; typical application areas: components of organic chemical process processes containing chlorides, especially where acidic chloride catalysts are used; cooking for the pulp and paper industry Absorber and bleach tank, absorption tower in flue gas desulfurization system, reheater, flue gas inlet baffle, fan (humidity), agitator, deflector and flue, etc.; used to manufacture equipment used in acid gas environment and components; acetic acid and acetic anhydride reaction generators; sulfuric acid condensers

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.