- Top Star Metal Materials Co.,Ltd

Name:Inconel 713C K418

Material:Inconel 713C K418

Diameter:3-550mm

Thickness:0.3-150mm

Length:2000-6000mm

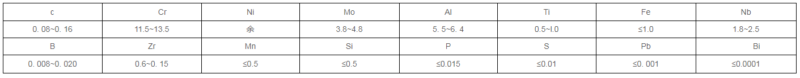

Inconel 713C K418, K18, W.Nr. 2.4670 is a γ’ phase precipitation strengthened nickel-based casting superalloy. It has good creep strength, thermal fatigue performance and oxidation resistance below 900°C. The alloy composition is relatively simple, does not contain cobalt, and has a low density, and is usually used in the cast state. The use of hot isostatic pressing (HIP) treatment and subsequent heat treatment can improve plasticity and fatigue properties, and can also restore the structure and performance of parts that have been degraded and performance-reduced after long-term use. Long-term aging at 800°C will precipitate a small amount of σ phase, but it has no obvious effect on performance. The alloy is suitable for making turbine rotor blades, guide vanes, monolithic turbines and other high-temperature parts of gas turbines working below 900 °C.

The alloy has been widely used as working blades, guide vanes and integral casting turbines of aviation, ground and offshore gas turbines working below 900°C, and is also widely used as supercharged turbines and hot extrusion dies for diesel and gasoline engines.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.