- Top Star Metal Materials Co.,Ltd

Name:nickel wire

Grade:Ni200/Ni201 (N4/N6)

Diameter:0.025-10mm

Length:custom

Package:wooden box

Ni201 pure nickel is a pure nickel grade with extremely low carbon content. It has been used to serve high temperature environments up to 1230 °C. It has excellent corrosion resistance to caustic soda, chlorine, etc. In particular, it is used in the material environment of diaphragm electrolytic caustic soda production equipment. Similar grades of Ni201 are Alloy 201, N02201, 2.4068, Nickel 201. Ni201 nickel wire has good mechanical strength, corrosion resistance and high heat resistance, and is suitable for making vacuum devices, electronic instrument components, and filters for chemical production of strong alkalis. Ni201 pure nickel product is suitable for radio, electric light source, machinery manufacturing, chemical industry, and is an important structural material in vacuum electronic devices.

Ni200 pure nickel alloy has a slightly lower nickel content than Ni201, in which the content of Ni and Co is greater than 99.5%, and the content of other impurities is not higher than 0.5%. Ni200 has the characteristics of acid and alkali resistance, especially its outstanding alkali corrosion resistance. It has excellent alkali and neutral solution medium for carbonate, nitrate, sulfate, chloride and acetate salt Corrosion resistance, stable performance in atmosphere, fresh water and sea water. At the same time, it also has good processing performance and high electric vacuum performance. Therefore, Ni200 is widely used in chemical, chemical, mechanical and electronic industries, and is mainly used to make various alkali-resistant equipment.

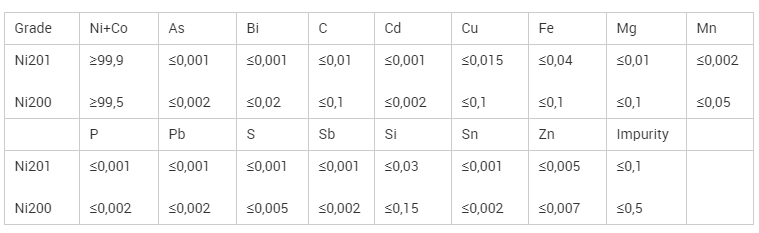

Chemical:

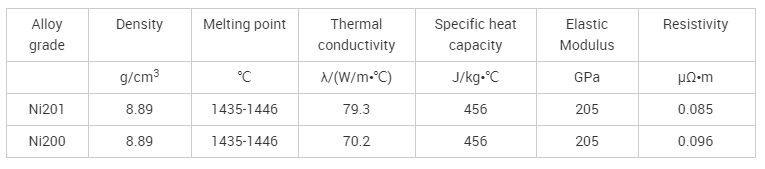

Our company has advanced equipment, including forging equipment. Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shape and size. Forging (forging and Stamping) one of the two major components. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. At the same time, we also have pipe welding machines, CNC lathes, milling machines, CNC machining centers and other equipment to produce each product with high quality.

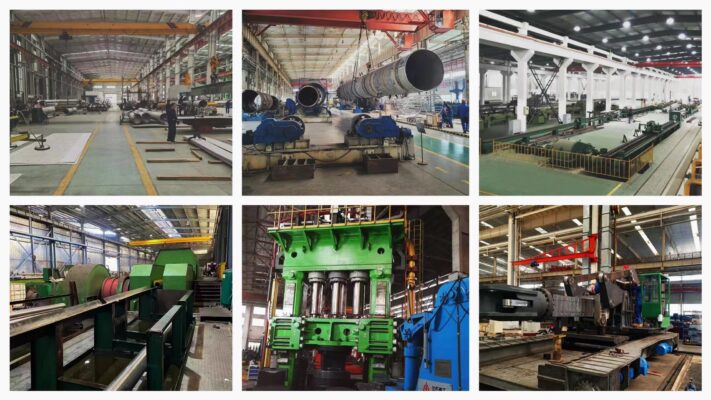

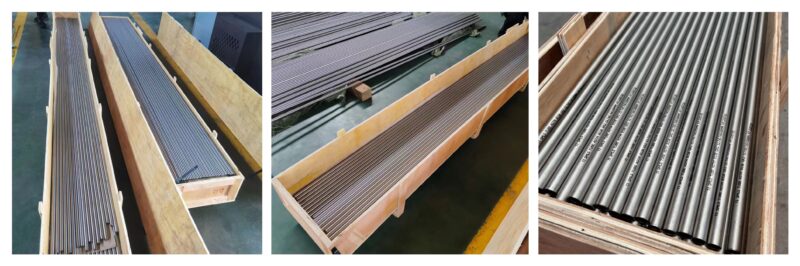

We use export standard fumigated wooden boxes, pearl film for wrapping, and cling film for surface protection, and do every detail well in an all-round way.

Top Star Metal Materials Co.,Ltd

E-mail:Abby@topstitanium.com

E-mail:sales@topstitanium.com

Whatsapp: 86-18292713888

Tel: 86-18292713888

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.