- Top Star Metal Materials Co.,Ltd

1. Small density and high strength: The density of titanium metal is 4.51g/cm3, which is higher than aluminum but lower than steel, copper and nickel, but its specific strength is the first among the above metal materials.

2. High corrosion resistance: Titanium is very stable in many media, such as titanium is extremely corrosion-resistant in oxidizing, neutral and weakly reducing media.

3. Heat resistance and low temperature resistance: the new titanium alloy screw can be used for a long time at a temperature of 600°C or higher. Low-temperature titanium alloys represented by titanium alloys TA7 (Ti-5Al-2.5Sn), TC4 (Ti-6Al-4V) and Ti-2.5Zr-1.5Mo maintain good ductility and Toughness, avoiding metal cold brittleness, is an ideal material for cryogenic containers, storage tanks and other equipment. Most of the titanium screws produced by Shishitong Metal are directly supplied to submarines, aviation power, high-end kitchen utensils, and driverless cars, so that they can not only withstand high temperatures, but can also be used normally at ultra-low temperatures.

4. Titanium is a non-magnetic metal, non-toxic, and will not be magnetized in a large magnetic field. With the enhancement of everyone’s health awareness, titanium screws are widely used in medical auxiliary treatment. Titanium screws have good compatibility with human tissue and blood even in the human body. At present, the main products of titanium are heart stents, intramedullary nails, dental implants, therapeutic instruments and some physical therapy equipment that have a lot of contact with the human body. The fastener components in these devices must also be titanium products.

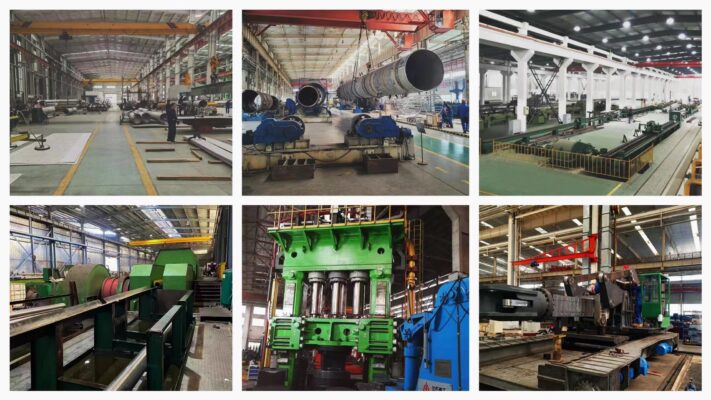

Top Star Metal Materials Co.,Ltd has a professional technical team, has strict control of materials and standards, and has mature technologies in hot rolling and cold rolling, forging, annealing, and we have chemical composition, mechanical properties, flaw detection, penetration and other aspects of products. Testing, with authoritative certification.

Top Star Metal Materials Co.,Ltd has advanced equipment, including forging equipment. Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shape and size. Forging (forging and Stamping) one of the two major components. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. At the same time, we also have pipe welding machines, CNC lathes, milling machines, CNC machining centers and other equipment to produce each product with high quality.

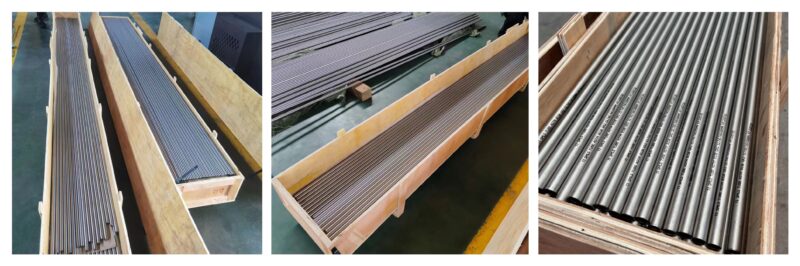

We use export standard fumigated wooden boxes, pearl film for wrapping, and cling film for surface protection, and do every detail well in an all-round way.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.