- Top Star Metal Materials Co.,Ltd

Product Name: Titanium tube/pipe

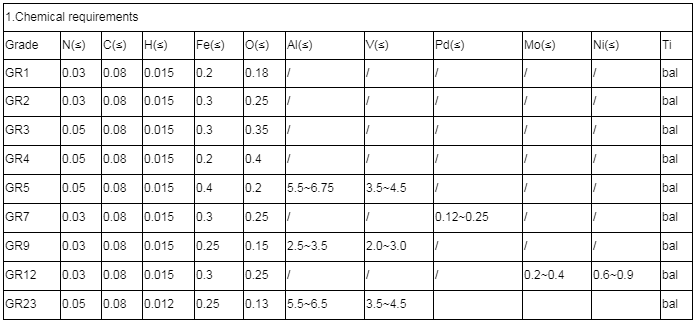

Grade: Gr9

Outside diameter:≤118mm

Wall thickness:≥0.5mm

Length:≤6000mm(max)

Technique: Cold Rolled, hot rolled

Material:Titanium

Surface:Polished

Standard:ASTM B338/ASTM B861

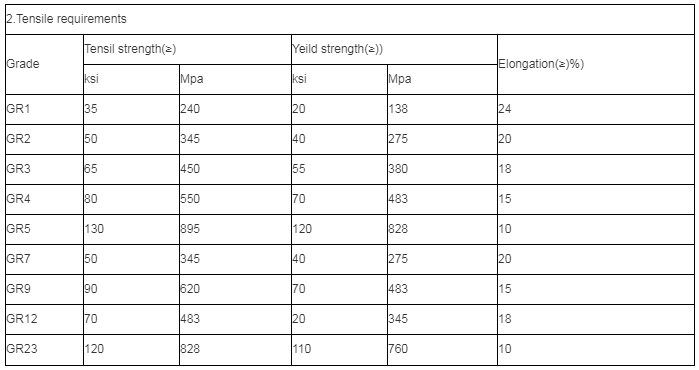

Titanium alloy Gr.9, also known as titanium alloy Ti-3Al-2.5V, is a common titanium alloy material. It is primarily composed of aluminum (Al) and vanadium (V) elements along with pure titanium (Ti). Gr.9 titanium alloy exhibits excellent mechanical properties, corrosion resistance, and high-temperature stability, making it widely used in aerospace, medical devices, chemical equipment, and other industries. This titanium alloy typically possesses high strength and low density, making it an ideal choice for many applications.

The density of titanium alloy is generally about 4.51g/cubic centimeter, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels.

The service temperature is several hundred degrees higher than that of aluminum alloy, and it can still maintain the required strength at medium temperature, and can work for a long time at a temperature of 450-500°C. These two types of titanium alloys still have high strength in the range of 150°C-500°C. Specific strength, while the specific strength of aluminum alloy decreases significantly at 150 °C. The working temperature of titanium alloy can reach 500°C, while that of aluminum alloy is below 200°C.

Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than stainless steel.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.