- Top Star Metal Materials Co.,Ltd

Name:titanium target

Size:custom

Purity:99.6%/99.7%/99.9%/99.95%/99.99%

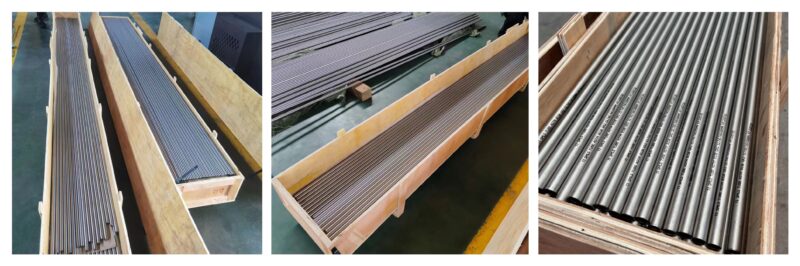

Package:wooden box

High Purity 99.99% Titanium Gr.1 Target are mainly used as semiconductor materials and getter materials in ultra-high vacuum devices. High-purity titanium has gettering properties, especially hydrogen, CH4, Co2 gas, so it can be widely used in high vacuum and ultra-high vacuum systems. When high-purity titanium sputtering is used to fabricate LSI, VLSI, ULSI circuit nets, these integrated components can be made extra light, thin, small in size and dense in lines. High-purity titanium targets can also be used as barrier metal materials.

Titanium target is one of the commonly used targets for preparing PVD coatings, and it is widely used in magnetron sputtering technology. Therefore, the quality of titanium targets is very important, and only good titanium targets can prepare qualified PVD coatings

The purity of the titanium target has a great influence on the performance of the sputter coating. The higher the purity of the titanium target, the less impurity element particles in the sputtered titanium film, resulting in better PVD coating performance, including better corrosion resistance and electrical and optical properties. However, in practical applications, titanium targets for different purposes have different requirements for purity. The target material is used as the cathode source in sputtering, and the impurity elements and porosity inclusions in the material are the main pollution sources of the deposited film. The porosity inclusions will be basically removed during the non-destructive testing of the ingot, and the porosity inclusions that are not removed will cause discharge during the sputtering process, thereby affecting the quality of the film; the content of impurity elements can only be reflected in the test results of full element analysis , the lower the total impurity content, the higher the purity of the titanium target

Usually the titanium target has a polycrystalline structure, and the grain size can range from micrometers to millimeters. The sputtering rate of the fine-grained target is faster than that of the coarse-grained target. The sputtering surface has a small difference in grain size. The thickness distribution of the shot-deposited film is also relatively uniform. The study found that if the grain size of the titanium target is controlled below 100 μm, and the variation of the grain size is kept within 20%, the quality of the sputtered film can be greatly improved.

Titanium has a close-packed hexagonal structure. Since the atoms of the titanium target are easily sputtered along the hexagonal close-packed direction of the atoms during sputtering, in order to achieve a higher sputtering rate, the crystal structure of the target can be changed by changing the method. to increase the sputtering rate. The crystallographic direction of the titanium target also has a great influence on the thickness uniformity of the sputtered film.

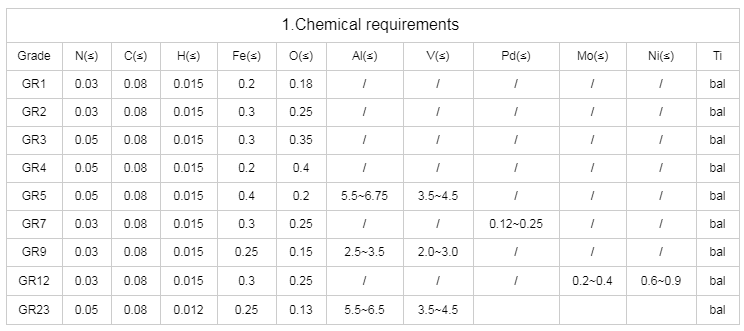

Titanium Target Chemical Requirements

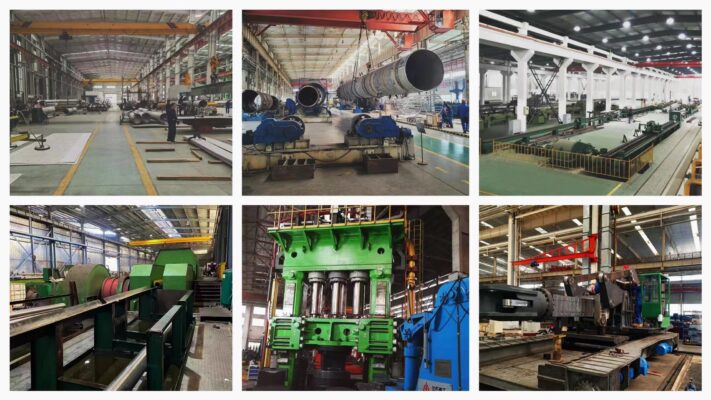

Our company has a professional technical team, has strict control of materials and standards, and has mature technologies in hot rolling and cold rolling, forging, annealing, and we have chemical composition, mechanical properties, flaw detection, penetration and other aspects of products. Testing, with authoritative certification.

Our company has advanced equipment, including forging equipment. Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shape and size. Forging (forging and Stamping) one of the two major components. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. At the same time, we also have pipe welding machines, CNC lathes, milling machines, CNC machining centers and other equipment to produce each product with high quality.

We use export standard fumigated wooden boxes, pearl film for wrapping, and cling film for surface protection, and do every detail well in an all-round way.

Top Star Metal Materials Co.,Ltd

E-mail:Abby@topstitanium.com

E-mail:sales@topstitanium.com

Whatsapp: 86-18292713888

Tel: 86-18292713888

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.