- Top Star Metal Materials Co.,Ltd

Name:Tungsten Plate

Standard:ASTM B760

Width:customized

Material:tungsten

Size:Custom

MOQ:1 Piece

Shape:Plate/sheet/foil

Surface Condition:polished

Tungsten plate has high hardness and high melting point, and is not eroded by air at room temperature; its main uses are for the manufacture of filaments, high-speed cutting alloy steel, superhard molds, and also for optical instruments and chemical instruments.

Tungsten plate rolling can be divided into hot rolling, warm rolling and cold rolling. Due to the large deformation resistance of tungsten, ordinary rolls cannot fully meet the requirements of tungsten sheet rolling, and rolls of special materials should be used. During rolling, the rolls should be preheated. According to different rolling conditions, the preheating temperature is 100~350℃. When the relative density of the blank is greater than 90%, it can be processed, and when the density of the blank is 92 to 94%, the processing performance is good. The hot rolling billet temperature is between 1350 and 1500 ℃, and the deformation parameters of the billet are improperly selected, and the billet will be delaminated. The starting temperature of warm rolling is 1200°C, and the thickness of the hot-rolled sheet with a thickness of 8 mm can reach 0.5 mm after warm rolling.

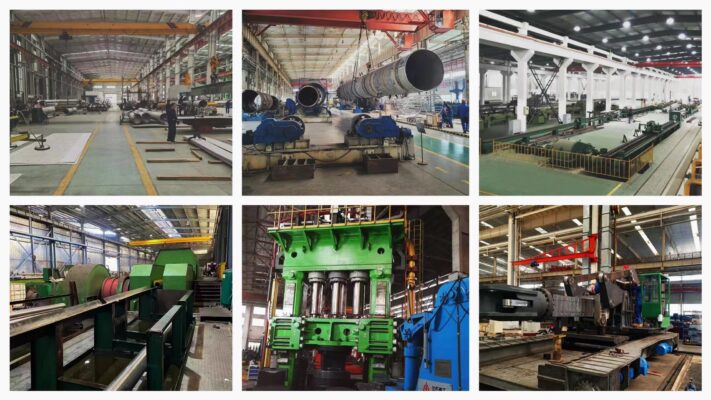

Our company has a professional technical team, has strict control of materials and standards, and has mature technologies in hot rolling and cold rolling, forging, annealing, and we have chemical composition, mechanical properties, flaw detection, penetration and other aspects of products. Testing, with authoritative certification.

Our company has advanced equipment, including forging equipment. Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shape and size. Forging (forging and Stamping) one of the two major components. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. At the same time, we also have pipe welding machines, CNC lathes, milling machines, CNC machining centers and other equipment to produce each product with high quality.

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.