- Top Star Metal Materials Co.,Ltd

Name: Tungsten Wire

Material:W1

Purity:99.95%

Density:19.3g/cm3

Application:Wire Heater

Name: Tungsten Wire

Material:W1

Purity:99.95%

Density:19.3g/cm3

Application:Wire Heater

Tungsten Wire is a fine wire-like material made of tungsten. Due to tungsten’s high melting point and excellent high-temperature resistance, tungsten wire finds wide applications in various fields.

Tungsten wire is typically characterized by high strength, high melting point, and good electrical conductivity, making it an ideal choice for many applications. For example, tungsten wire is commonly used in electronic devices, lighting fixtures, vacuum melting, glass processing, and heat treatment. In the electronics field, tungsten wire is used in filaments, electron guns, and high-temperature resistors. In lighting, tungsten wire is utilized as the filament in light bulbs. In glass processing and heat treatment, it can be used as heating elements and in high-temperature furnaces.

Tungsten wire is also commonly employed as an electrode in inert gas shielded welding processes, such as tungsten inert gas (TIG) welding. Its high melting point and corrosion resistance allow it to withstand high temperatures and chemical environments.

In summary, tungsten wire is a fine wire-like material made of tungsten, known for its high strength, high melting point, and excellent high-temperature resistance. It finds widespread applications in electronics, lighting, glass processing, heat treatment, and welding industries.

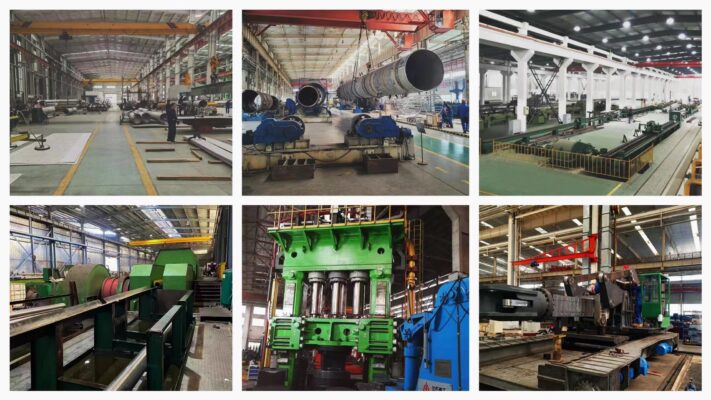

Top Star Metal Materials Co.,Ltd has a professional technical team, has strict control of materials and standards, and has mature technologies in hot rolling and cold rolling, forging, annealing, and we have chemical composition, mechanical properties, flaw detection, penetration and other aspects of products. Testing, with authoritative certification.

Top Star Metal Materials Co.,Ltd has advanced equipment, including forging equipment. Forging is a processing method that uses forging machinery to apply pressure to metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, certain shape and size. Forging (forging and Stamping) one of the two major components. Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. At the same time, we also have pipe welding machines, CNC lathes, milling machines, CNC machining centers and other equipment to produce each product with high quality.

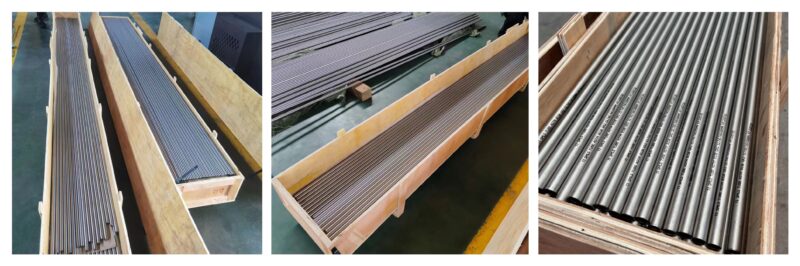

We use export standard fumigated wooden boxes, pearl film for wrapping, and cling film for surface protection, and do every detail well in an all-round way.

Top Star Metal Materials Co.,Ltd

E-mail:Abby@topstitanium.com

E-mail:sales@topstitanium.com

Whatsapp: 86-18292713888

Our company was founded in 2005, committed to providing professional technology for aerospace, military, industrial, medical, and has a professional team to provide technical support.