What are the properties of Gr.5 titanium alloy?

1.Gr.5 titanium alloy belongs to type α+β alloy. 2.Gr.5 has good process performance 3.The Gr.5 titanium alloy after deformation processing can be heat treated by stress annealing (600 degrees Celsius), ordinary annealing (700-800 degrees Celsius), recrystallization annealing (940 degrees Celsius) and double annealing (940 degrees Celsius). The structure obtained by stress relief annealing and ordinary annealing is non-recrystallized or partially recrystallized structure with high strength. 4.Gr.5 diamond alloy is strengthened by heat treatment, and its strength can be increased by 20%-30%. It is generally believed that it can have good comprehensive performance at 850-950 degrees Celsius. 5.Gr.5 titanium alloy has good weldability, and the temperature of the weld zone is not lower than 90% of the matrix. 6.The corrosion resistance of Gr.5 titanium alloy is next to that of pure titanium. It can work for a long time below 400 degrees Celsius, and the temperature can reach 700-750 degrees Celsius for a short time. When the oxygen and nitrogen content in the alloy are at low levels, TC4ELI titanium alloy can also It maintains good plasticity at -196 degrees Celsius and can be used to make low-temperature and high-pressure containers.What are the components of Gr.5 titanium alloy?

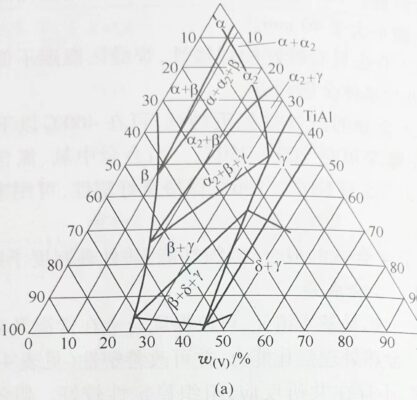

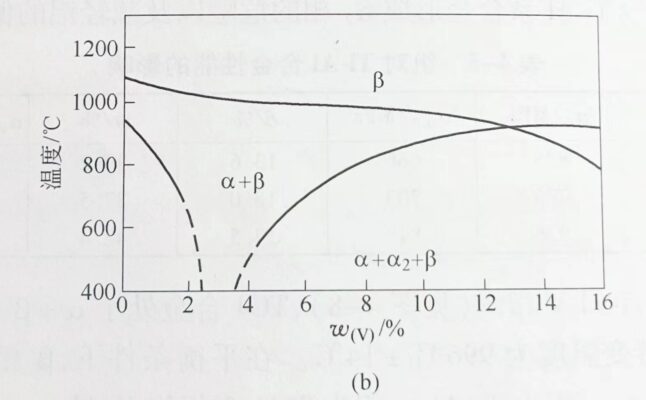

Aluminum in Gr.5 titanium alloy is a basic element, which can ensure the performance of the alloy at room temperature and high temperature. Vanadium can increase the heat treatment strengthening ability of the alloy and can improve the plasticity. Vanadium is a β isocrystal element, there is no eutectoid reaction, and the structure stability is good. Another function of vanadium is to reduce the formation of α2 in Ti-Al alloys.Heat Treatment of Gr.5 Titanium Alloy

Gr.5 commonly used heat treatment is annealing and quenching aging. Ordinary annealing is heated to 750-800 degrees Celsius, and the heat preservation is 1-2 air cooling to obtain an incomplete recrystallization structure, so it is called incomplete annealing. The recrystallization annealing heating temperature is higher (930-950 degrees Celsius) to ensure sufficient recrystallization. The quenching and aging process is generally heated to 930-950 degrees Celsius, water-cooled, and aged at 540 degrees Celsius for 4-8 hours.Ti-Al-V ternary phase diagram (a) and vertical interface of 6%Al (b)