Titanium Rod

Titanium rods and titanium alloy rods are new structural materials. Because titanium has a high melting point, small specific gravity, high specific strength, good toughness, fatigue resistance, acid and alkali corrosion resistance, low thermal conductivity, and good high and low temperature tolerance, it can be used in rapid cooling Under the condition of rapid heat, the stress is small and so on. It is used in high-tech fields such as aviation and aerospace, and is continuously promoted to industries such as chemical industry, petroleum, electric power, seawater desalination, construction, and daily necessities.

(1).

Good corrosion resistance. Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is far superior to that of stainless steel; it has particularly strong resistance to pitting corrosion, acid corrosion, and stress corrosion; it is resistant to alkali, chloride, chlorine, organic substances, nitric acid, and sulfuric acid. etc. have excellent corrosion resistance. However, titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.

(2).Good low temperature performance. Titanium alloys can still maintain their mechanical properties at low and ultra-low temperatures. Titanium alloys with good low temperature performance and extremely low interstitial elements, such as TA7, can maintain certain plasticity at -253°C. Therefore, titanium alloy is also an important low-temperature structural material.

(3).Chemically active. Titanium has high chemical activity and has strong chemical reactions with O, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere. When the carbon content is greater than 0.2%, hard TiC will be formed in the titanium alloy; when the temperature is high, it will also form a hard TiN surface layer when it interacts with N; when the temperature is above 600°C, titanium absorbs oxygen to form a hardened layer with high hardness ; When the hydrogen content rises, an embrittlement layer will also be formed. The depth of the hard and brittle surface layer produced by absorbing gas can reach 0.1-0.15 mm, and the degree of hardening is 20%-30%. The chemical affinity of titanium is also large, and it is easy to cause adhesion with the friction surface.

(4).Thermal conductivity is small. The thermal conductivity of titanium λ=15.24W/(m.K) is about 1/4 of nickel, 1/5 of iron, and 1/14 of aluminum, while the thermal conductivity of various titanium alloys is about 50% lower than that of titanium.The modulus of elasticity of titanium alloy is about 1/2 of that of steel, so it has poor rigidity and is easy to deform. It is not suitable for making slender rods and thin-walled parts. times, resulting in severe friction, adhesion, and bond wear on the flank of the tool.

3.Titanium grade

China:TA1、TA2、TA3、TA7、TA9、TA10、TA15、TA18、 TC4、TC4ELI、TC6、TC9、TC10、TC11

US:GR1、GR2、GR3、GR5、GR7、GR12

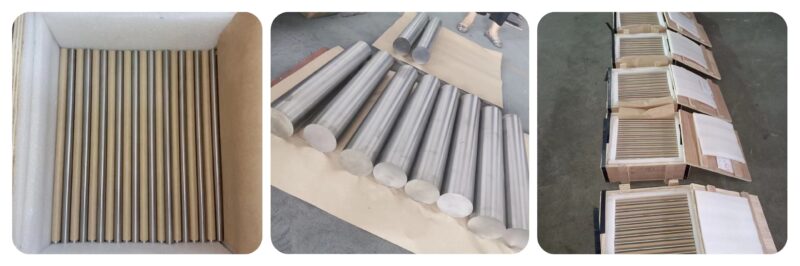

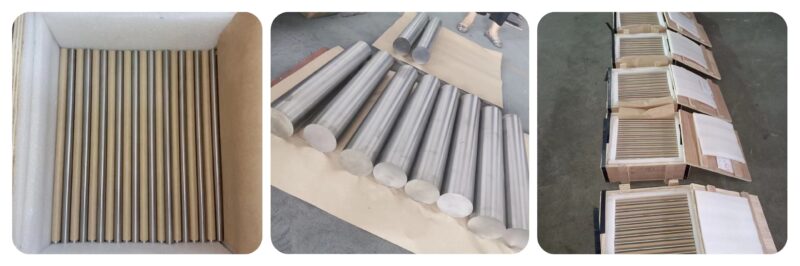

4.Product Show